Fermentation Aid

fermentation aids significantly enhance the ability of yeast to compete with undesirable microorganisms in the critical initial stages of propagation and fermentation. They boost the metabolic functions of yeast and create a more favorable environment for yeast propagation.

KL Solutions fermentation aids effectively control undesirable microorganisms while simultaneously promoting and aiding yeast propagation in the ethanol fermentation process. This family of proprietary, antibiotic-and enzymatic products includes technologies specifically designed for propagation and fermentation as well as technologies that can be fed upstream for plant-wide control of competing microorganisms. Patented and patent-pending products are available.

Fermentation processes using KL Solutions fermentation aids typically achieve value-added benefits including:

- Improved microbiological control

- Enhanced yeast viability

- Improved fermentation efficiency

- Increased ethanol yields

- Improved profitability

How They Work

These fermentation aids significantly enhance the ability of yeast to compete with undesirable microorganisms in the critical initial stages of propagation and fermentation. They boost the metabolic functions of yeast and create a more favorable environment for yeast propagation.

The aids also hinder the propagation of undesirable microorganisms. They do so by damaging or destroying the cell membranes of these microorganisms, rendering them unable to effectively compete with yeast.

The products complement most fermentation processes in use today, including Isobutanol and second-generation processes. They are effective in both high and low pH systems.

Product Description

BIOCIDES FOR DISTILLERY (KL- BIOCIDE M)

INTRODUCTION

- Biocides are chemical compounds. It is general name for any substance that kills or inhibits the growth o microorganisms such as bacteria, molds, slimes, fungi, etc. Many of them are also toxic to humans. Biocidal chemicals include chlorinated hydrocarbons, organometallics, and halogen releasing compounds, metallic salts, organic Sulphur compounds, quaternary ammonium compound, and phenolics. It is 100 % eco. Friendly and safe for use.

- How and why do Microorganisms Make Alcohol?

Energy conversion by living cell is the fundamental property. Living cells produce useful energy ATP, which is regarded as the cell’s energy currency.

Yeast has the property to maintain the stock of ATP, which is possible due to the consumption of sugars like glucose, and fructose. Sucrose is the main component of sugar-cane juice which consists of the glucose molecule attach to the one molecule of fructose. The first step of yeast’s activity is to break apart the glucose and fructose units which enter the energy metabolization machinery to provide energy.

If yeast grown in oxygenated medium, the sugar will be broken down step by step, into smaller and smaller molecules and at the end carbon dioxide is liberated. However, if there is little oxygen or no oxygen available to the yeast the series of chemical breakdown processes cannot be completed and the sugar is broken down into ethanol-a fuel alcohol.

C6H12O6 = 2C2H5OH + 2CO2

DGO = - 56 Cal

Glucose is splited up into two molecules of pyruvic acid via the reactions of glycosis. Alcoholic fermentation and aerobic degradation follow the same reaction frequencies up to this point. In fermentation pyruvic acid is degraded enzymetically to alcohol and carbon dioxide.

- Mode of Action

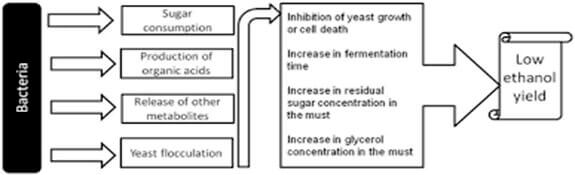

Bacterial contamination of molasses in the fermentation process leads to many critical problems during alcohol production. Reduction of fermentation efficiency low alcohol yield and increased volatile acidity are the basic problems associated with bacterial contamination.

KL- BIOCIDE-M is a specially developed biocide which effectively controls the losses during fermentation process by checking the bacterial contamination.

It is a blend of two types of yeast friendly biocides which acts on the principle of bacteriostatic agent. Its broad-spectrum action inhibits the micro-organisms effectively thereby minimizing process disruptions in terms of yield and efficiencies.

- KL- BIOCIDE-M FOR DISTILLERY FERMENTATION PROCESS

Bacterial contamination of molasses in the fermentation process leads to many critical problems during alcohol production. Increased contamination loads coming from molasses get aggravated during fermentation stage due to more dilution with water. Reduction of fermentation efficiency, low alcohol yield and increased volatile acidity are the basic problems associated with the bacterial contamination. Presence of bacteria suppresses the yeast growth and in no time it affects the yeast population. Hence it is necessary to control bacterial contamination in the fermentation process for better yields and better efficiencies.